AAI sales engineers work with our customer base to design and source highly technical components and assemblies produced by the below manufacturing processes. We have cultivated vast technical and commercial experience to make both our principals and customers successful on the most cutting edge products in the automotive industry.

casting

Non-Ferrous (Al, Mg, Zn)

High Pressure

Permanent Mold

Air-Set Sand

Semi-solid Thixocasting

Ferrous Casting

DISA – Ductile Iron

Electromagnetics

Solenoids

Actuators

Stators

Engineered Coils

aluminum extrusion

Machining, Bending

Anodizing

Forging

Closed Die Hot Forging

Cold Forging

Cold Heading

gear Production

Spur, Helical, Bevel, Shafts

Hobbing

Gear Grinding

Skiving

Shaping

Knitted wire mesh

Heat Shields

Anti-Vibration Isolators

Airbag and Safety Critical Filters

Engine Breathers

Silencers and Muffler Packings

Separation and Spacer Rings

Exhaust Decoupling Ring

Mesh Sleeves

Catalytic Convertor Mesh Wraps

MACHINING

Vertical

Horizontal

Palletized

From Cast, Forged, Extruded

Blanks

powder metallurgy

Precision Gearing

(Spur & Helical)

Structural Components

Plastic molding

Insert Molding

Reel-to-Reel Molding

Custom Connectors

Sealing, Testing, Automation

Conventional Molding

Standard Resins

High Performance Resins

Two-Shot Molding

precision turning

Screw Machining

CNC Multispindle

Swiss Machining

Rotary Transfer

Grinding & Finishing

preg panel molding

Load floors and sunshades

Thermoset Baypreg Molding

Carpet wrap and assembly

Die-cutting

3D Printing

Stereolithography (SLA)

Multi Jet Fusion (MJF)

Fused Deposition Modeling

(FDM)

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering

(DMLS)

prototyping

Machining

Laser & Waterjet Cutting

Sheet Metal Fabricating

Casting

Air-set Sand

Plaster Cast

Graphite Die Cast

3D Printing

Stamping

Fineblanking

Progressive Die

High Speed Stamping

Line Die

Transfer Die

Transfer & Servo Press

Resistance Welding

Robotic MIG Welding

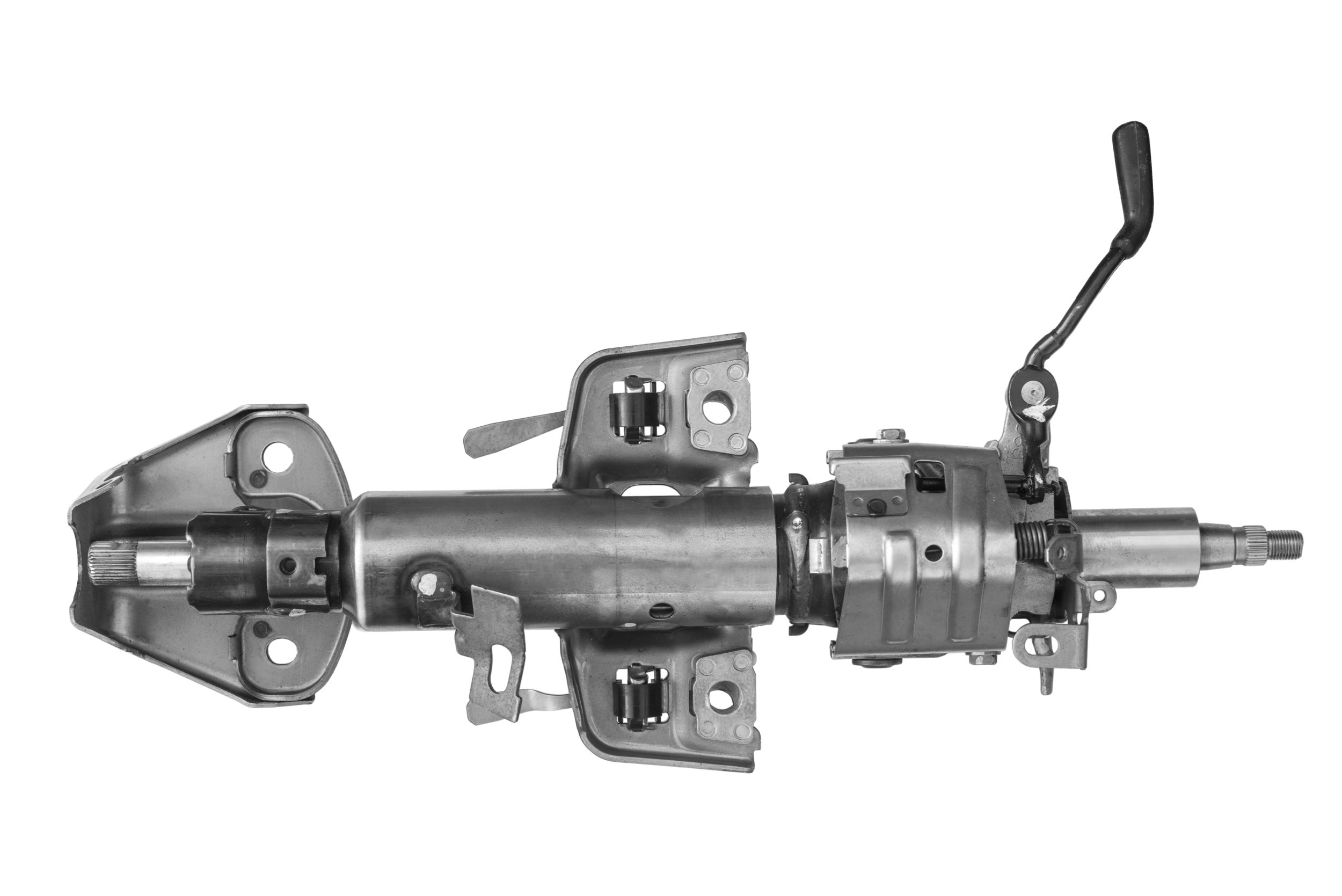

complex subassembly

Product Design

Automated & Manual